The metal-stamping process is described in general, focusing on

types of stamping presses and tooling, as well as other equipment that

comprises a complete stamping-press line. The use of forming lubricants

and the process of part design is also discussed.

A stamping operation requires talented people and the right

equipment to perform successfully. How does the stamping process work,

and how are equipment and personnel employed to make sure quality parts

are stamped consistently?

A stamped sheetmetal part requires able creators backed by talented

personnel who allow their machinery—from stamping presses to

tooling--to reach its technological potential.

Designing a part

The birth of a stamped metal part is the designer’s drawing board,

perhaps the result of a request from a specifier. The designer must

plan a particular part while considering a multitude of factors. How is

the part expected to interact with other parts and best fit into a

component or assembly? Must the part be light in weight? What forces

must it withstand? How long must it last? What size should it be? What

is the environment, and how will material selection influence how the

part performs in that environment? What technology and machinery is

available in order to construct this part in an efficient and

cost-effective manner? Will the part be coated or must it be cleaned?

If so, how does that affect the choice of material and types of

lubrication required for manufacture?

Quality people and equipment required

Questions asked and answered, the proposed part enters the realm of

manufacturing. The effective metal-stamping operation, especially an

operation serving multiple clients with multiple requirements, boasts

an array of flexible equipment engineered and maintained to efficiently

produce a variety of parts. The employees overseeing and operating

shop-floor machinery must be well-trained to take advantage of the

technology.

Stamping presses serve specific needs

Obviously, stamping presses are the heart of any sheetmetal-stamping

operation. Presses come in varying tonnages, configurations and means

of operation. The majority of stamping presses can be classified as

mechanical or hydraulic. Mechanically driven presses typically boast

higher operating speeds—surpassing 2000 strokes/min. to produce parts

rapidly. Relatively simple 2D parts are ideally created in mechanical

presses, parts such as razor blades or electrical contacts.

Hydraulically powered presses traditionally offered force control

throughout the entire forming stroke, unlike traditional mechanical

presses that ramp up force as the press ram descends on the work

material. Though typically slower than mechanical presses, hydraulic

presses, with this total force control, have been the machinery of

choice to produce deeper 3D parts with cup or sink recesses. Producing

parts with depth in a stamping press is referred to as drawing.

In recent years, these formerly cut-and-dried distinctions between

mechanical and hydraulic presses have blurred as new press and

press-control technologies enable each to assume characteristics of the

other. A newer development, servo-powered presses, which are

technically mechanical presses often referred to as servo presses,

utilize servo drives to bring benefits of hydraulic and mechanical

presses into a single machine.

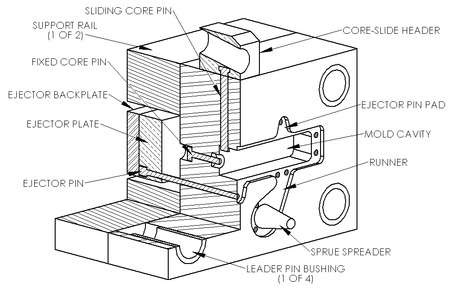

Increasingly complex tooling

Of course, a stamping press would just be a machine that makes noise

were it not for the tooling inside. One-hit dies represent the simplest

form of tooling, where one press hit pounds out a complete part, or at

least a shape that travels to secondary machinery for completion or to

another one-hit die in another press. Progressive dies, containing

multiple stations, add features to a part with each press hit as the

base material travels along the die in a strip, knopwn as a carrier

strip. In this manner a part is progressively formed. Transfer dies can

be considered a combination of one-hit and progressive dies. Here, a

material blank—without a carrier strip--travels from die to die,

eventually forming a complete part. Many large drawn parts are produced

via transfer dies. Transfer dies require mechanisms to physically lift

a part from one die station and deposit it into the next. This is

accomplished through the use of a transfer press—essentially a

specialized mechanical press—or via a part-transfer system attached to

an existing press.

Over the years, owing to new technology and efforts to reduce costly

and time-consuming secondary operations that take place away from the

press, more and more work occurs in the tooling. The result: more

complicated and costly stamping dies. Given this fact, die design,

maintenance, protection and utilization are so important to the

metal-stamping process that a manufacturer will have on staff personnel

dedicated to tooling issues.

The high cost of hard tooling such as stamping dies, and the care

required to allow this tooling to produce part after part to rigid

specifications, demand attention to detail in this area. To protect

tooling, a die designer or metal stamper will incorporate various

controls and sensors into the process. Often, sensors will be embedded

into tooling to ensure presence, and correct orientation and shape of

the part material. Die components such as punches may be built with

and/or coated with special material. These tool coatings allow for

creation of higher-quality stampings while increasing tool life. Many

stamping operations, especially those tasked with performing multiple

jobs on a single press line, incorporate quick-die-change (QDC)

equipment. Such equipment—rolling bolsters, die carts, clamps,

etc.—allow rapid changeout of tooling from one job run to the next in

order to keep presses running.

Forming lubricants are key to part quality and equipment life

Proper lubrication within the tooling is essential to the protection

of dies and presses, and also to the production of quality parts.

Depending on the part material, type of part to be produced and type of

tooling employed, specific forming fluids are used. Various lubricant

formulations exhibit properties that best serve specific stamping

requirements. In some cases, material is coated with lubricant prior to

entering the press. In other cases, forming fluids are applied to the

part material and tooling during the stamping process.

Lubricant selection reaches beyond part, tooling and material

considerations. More and more, safety and regulatory concerns affect

selection. Lubricants may be required to be reclaimed or disposed of

safely, and must not pose a hazard to employees or the environment.

Stamping-lubricant and lube-system suppliers have, therefore, developed

fluid formulations and methods of delivery and reclamation to address

these concerns.

Functional stamping-press line has many components

Stamping a part involves more than a press, tooling and forming

fluids. A fully outfitted press line includes feed machinery that

delivers part material to the press. This includes equipment to

transport stage and deliver coiled material into the press, or other

equipment to feed a press individual material blanks. In multiple-press

lines, robots or other part-handling machinery transport part material

from press to press, then capture finished parts for placement in bins

or racks. Conveyors or other material-handling equipment also move

parts or collect and transport scrap.