Tool

and die makers use computerized machine tools as well as ones that are

mechanically controlled to make metal parts, tools and instruments. If

you are considering this as a career option, you will need to use

blueprints, drawings, or computer-aided design files to make tools and

dies. This may involve computing and verifying dimensions, shapes,

sizes, and tolerances of work pieces.

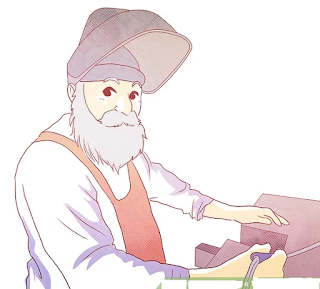

Toolmakers make precision tools that are used to cut and form metal

and other materials. They also create jigs that hold metal while it is

being bored or drilled. Die makers create metal forms that are used to

shape metal in forging and stamping operations.

Tool and Die Maker Career Snapshot

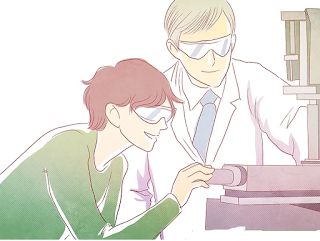

Tool

and die makers typically work in manufacturing settings such as machine

shops, or factories. Fabricated metals, machinery, and transportation

manufacturing are frequent employers. Although the work of tool and die

makers is not dangerous, you should still follow safety precautions if

this is your field. Be sure to wear protective equipment like safety

glasses, masks and earplugs. Most tool and die makers work full time,

sometimes during unusual hours if facilities are running shifts around

the clock. You may also have to work overtime hours.

Tool and Die Maker Career

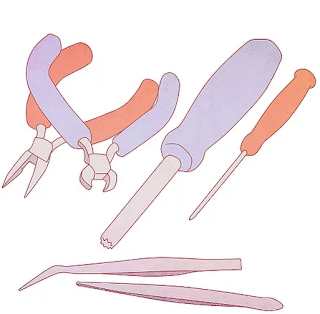

| Tool and Die Maker Skill Set: | Required Abilities: | Tools Used by Tool and Die Makers: | Typical Work Activities: |

|---|---|---|---|

| • Operation and Control • Critical Thinking • Operation Monitoring • Quality Control Analysis • Active Listening | • Near Vision • Visualization • Problem Sensitivity • Oral Expression • Category Flexibility | • Calipers • Drill press or radial drill • Gage block set • Power grinders • Squares | • Controlling Machines and Processes • Inspecting Equipment, Structures, or Material • Getting Information • Making Decisions • Processing Information |