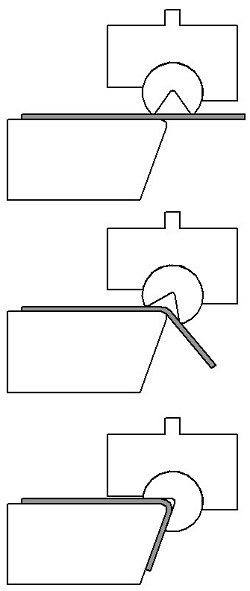

A

rotary die is a special type of punch die combination which bends the

sheet metal using a rotating cylinder with a v opening cut into the

side of the cylinder. The cylinder is seated into a saddle making up

the punch section of the die. The sheet metal lays on an anvil and

the rotary die is pushed down on top of it. As the die engages the

sheet it begins to rotate and bends the metal around the tip of the

anvil. Sometimes a backing plate (not shown) called a heel keeps the

saddle steady as the machine is closed and the bend completed.

Rotary

dies provide a number of benefits over traditional punch die

combination. The rotary die will clamp the sheet metal before bending

providing a secure work piece without any sliding. As the sheet is bent

the worker side does not move providing a safer and more ergonomic

experience for the operator. The fact that the sheet does not move

also means the the operator does not have to ‘chase’ the metal while

it’s being bent, improving the quality of the bend. Rotary dies can

also bend beyond 90 ° like traditional tooling to compensate for Spring Back.

Many operations can have their required tonnage reduced by using a

rotor die. Rotary dies also allow for the creation of complicated

setups which can quickly and accurately bend standardized profiles.

This can be beneficial for production type environments because it

takes less effort to create a consistent part.

Draw backs to

rotary bending include price and geometry limitation. Because of

their mechanical nature rotary dies can be comparatively expensive,

making them better suited for production type environments. Their

geometry will typically only allow the profile that they are designed

for to be bent, however clever design can allow bends which would be

difficult or impossible with traditional dies.

Because of their

advantages for standard production rotary dies are often used in

stamping operations in combination with other geometries rather than

on a press brake.

No comments:

Post a Comment