Shimming

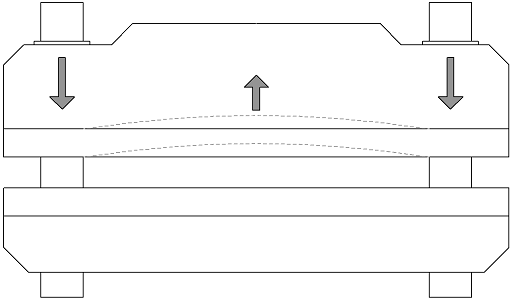

Proper

brake maintenance, cleaning of dies and careful alignment are key first

steps to ensuring accurate and reliable bending. However even after

taking the necessary precautions Bend Angles can still end up being

irregular across the length of the bend due to crowning or other

machine related flexing. The most common form of flexing that occurs

in a press brake is what is known as crowning. Crowning occurs when

the upper and lower beam, despite their often significant structure,

flex away from the work piece in the center of the brake. Most brakes

are driven by two points at either ends of the press. These points can

be the cams of a mechanical brake or the cylinders of a hydraulic

brake. The entire force of the brake is driven through these two

points, so the longer the beams, the more room for deflection. Below

shows a generic Brake Press

whose upper beam is undergoing crowning. Before using shims to recover

from the effects of crowning you should, if possible, bend your work

piece at the center of the brake. While this won’t eliminate the

crowning it will center it on your tooling, making it easier to

compensate for.

Once

the need for shimming has been established, and all other basic

assurances have been made that the machine is functioning properly, you

will begin to slowly add height to the areas where your Bend Angle

is large. The most effective method for shimming is removing the die

and placing a piece of paper under the area where you are looking to

shim. Depending on your v opening a single sheet of paper can add as

much as 1° to that area of the bend. The larger the v opening the more

shimming will be required to achieve this because the punch has to

travel further in order to affect the work piece. It is important to

stress this level of precision to new operators in order to prevent

dangerous over shimming on the first try.

Forming Shims

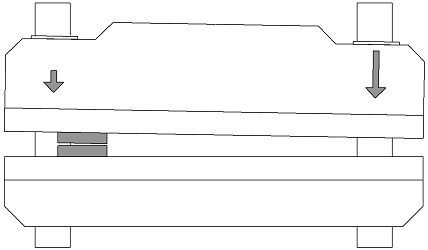

Another common situation which can be solved with shimming is the twisting of a Brake Press

when the tooling is off center. Many times a setup will call for

different sections of a Brake Press to be used to bend different parts

of a work piece. This typically involves moving the work piece from

one end to the other during the entire bending process. When the work

piece is at one end of the press it is going to unbalance the load at

the other end. This can at best force the machine to compensate with

hydraulics, and at worst cause a machine stop or failure. A Forming

Shim is a piece of the same material which, already bent, can be placed

inside the v opening at the far end of the brake, sometimes with the

addition of a paper shim, in order to balance the load at the bottom of

the bend. This type of shim can run the entire length of the Brake

Press is necessary in order to even out the load. Forming shims are

especially useful when Bottom Bending and Coining because the majority of the tonnage will be applied after the punch has made contact with the shim.

As

you can see above, a bend operation set up on the left end of the brake

causes uneven force to be applied, resulting in a twisting of the upper

beam. Even a single degree of rotation on the upper beam can be

significant to the operation of the press. In this operation adding a

forming shim to the right end of this brake would have prevented the

twisting from occurring.

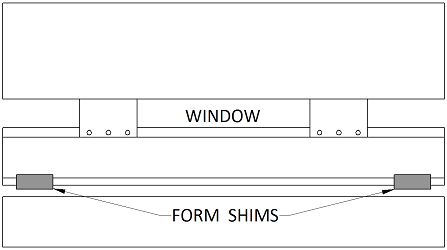

Forming Shims are also commonly seen on Window Punching operations because they

help re-balance the load back into the center of the punch. The shims

are added to the punch area outside of the window. This adds a layer

of protection against crowning inside the window area.

Warning about Shimming

As

we discussed proper maintenance, calibration and cleaning of your Brake

Press will eliminate the majority of accuracy issues seen by operators

in day to day operations. Most modern brakes have methods of

compensating for crowning and twisting which, while not always perfect,

can be highly effective at reducing inaccuracies. Coatings on

materials, material tolerances, and stickers or labels added to parts

can all cause bends to change along the bend lines. While form

shimming is rather benign, adding a shim underneath your die should be

a last resort at correcting parts. Over time the tooling will begin to

wear in, adding an additional level of wear around the shim, resulting

in the need for more shimming. This can make the problem worse and

eventually end up ruining the die.

No comments:

Post a Comment