The

term hemming has its origins in fabric making where the edge of cloth

is folded back on itself and then stitched shut. In sheet metal

hemming means to fold the metal back on itself. When working with a Brake Press hems are always created in a two step process:

- Create a bend with Acute Angle Tooling in the metal, 30° is preferable but 45° will work for some circumstances.

- Place the acute bend under a flattening bar and apply enough pressure to finish closing the bend.

The

first step is done the same as any regular acute angle bend. The

second stage of the hemming process requires some additional know how

on the part of the Brake Press operator

and tool designer because the angle of the sheet metal, the flattening

bar wants to slide down and away from the sheet metal. In addition the

work piece wants to slide out from between the bars. These two forces

are known as thrust forces.

This

requires that the flattening die be designed to withstand the thrust

forces and remain flat. In addition it requires that the operator put

a forward force against the sheet metal to prevent it from sliding out

of the die. These forces are most prominent on thicker work pieces

with shorter flanges. With these factors in mind let’s examine three

of the most common forms of hemming set ups and tooling available for

press brakes.

Multi Tool Setup, Acute Tooling and Flattening Die

The

simplest form of hemming set up is combining two different setups. The

first is an acute setup, where the 30° bend is created using standard

tooling. Once the first bend is made the part is either transferred to

another machine, or a new setup is put into the original. The second

setup is a simple flattening bar. The bend is placed underneath the

flattening bar and is closed. This setup doesn’t require any special

tooling and may be preferable for short runs, prototypes or job shops

which will need to form a variety of hem lengths. As individual pieces

of Brake Press Tooling the

acute tooling and flattening bar are very versatile, and add value

outside of hemming. The draw backs to this system is the obvious

requirement of two unique setups, as well there is no thrust control in

the flattening process.

Two Stage Hemming Punch and Die Combination

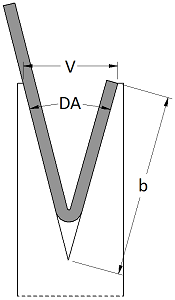

A

two stage hemming die works by using a deep channeled die and an acute

sword punch. The first bend uses the channel as a v opening to air

form the bend. In the second stage the punch slides into the channel

as the punch is closed and the edge of the punch is used to flatten the

sheet metal. Seating the punch inside the die’s channel redirects the

thrust force into the die, which can be more readily secured than the

punch itself. The drawback for this type of die is that it practically

requires a CNC control. Because of the difference in height between

the stroke of the first and second stage to adjust manually would be

very time consuming. In addition this type of die can be easily split

from over tonnage, reinforcing the need for

computer controlled safeties.

Three Stage Hemming Punch And Die

The

other most common form of tooling designed specifically for creating

hems is a three stage, or accordion type punch and die. The v opening

sits on top of a spring loaded pad, which sits over a bottom pad. In

the first stage the acute bend is created in the v opening after the

spring has been compressed and the upper pad is seated on the lower

pad. In the second stage the upper ram is retracted and the springs

between the upper and lower pad returns it to its original position.

The sheet metal is then placed between the upper and lower pad and the

punch is closed down transferring tonnage through the v die. Special

relief is given to the v die to allow this tool on tool interaction.

The guide between the upper and lower pad prevents the thrust forces

from affecting the rest of the tooling. The lower die also gives the

operator something to push the work piece against preventing the sheet

metal from sliding out. This tool is preferred for mechanical, non

CNC, brakes because the difference in stroke heights is very small,

making adjustment less time consuming. This set up also allows you to

use a standard acute punch.

Tonnage Required For Hemming

The

tonnage required for hemming is going to depend on the strength of your

material, its thickness and most importantly what type of hem you wish

to form. The tear drop and open hems do not require nearly as much

tonnage as a flat hem does. This is because you are only changing the

inside radius minimally, basically you are just continuing the bend

past 30°. When you flatten the metal you are forming a crease and

removing the inside radius. Now you are forming the metal rather than

simply bending it. Below you can see a hemming tonnage chart for cold

rolled steel.

| Metal Thickness | Open / Tear Drop Hem Tonnage | Finished Height | Closed Hem Tonnage | Finished Height |

|---|---|---|---|---|

| 24 Gauge | 15 | .118 | 35 | .048 |

| 22 Gauge | 20 | .118 | 50 | .060 |

| 20 Gauge | 25 | .137 | 60 | .072 |

| 18 Gauge | 26 | .137 | 80 | .096 |

| 16 Gauge | 38 | .181 | 95 | .120 |

| 14 Gauge | 50 | .216 | 130 | .150 |

| 12 Gauge | 90 | .255 | 180 | .21 |

| 10 Gauge | 100 | .314 | 210 | .269 |

| 8 Gauge | 140 | .445 | 280 | .329 |

Uses For Hems

Hems

are commonly used to re-enforce, hide imperfections and provide a

generally safer edge to handle. When a design calls for a safe, even

edge the added cost of material and processing of a hem is often

preferable to other edge treating processes. Designers should look

beyond a single small flat hem to treat edges. Doubling a hem can

create an edge perfectly safe to be handled without almost regard for

the initial edge quality. Adding a hem in the ‘middle’ of a bend

profile can open the doors to a variety of profiles not possible

without fasteners or welding. Even without sophisticated seaming

machines a combination of two hems can create strong, tight joints with

little or minimal fastening. Hems can even be used to strategically

double the thickness of metal in areas of a part which may require

extra support. Hems used in the food service industry should almost

always be closed for sanitary purposes (very difficult to clean inside

the opening).

Double Hem Edge – Hem And Double Metal Thickness Bend For Support – Using A Hem To Create Advanced Profiles

Determining Flat Patterns Of Hems

The

flat pattern of a hem is not calculated in the same fashion as a

typical bend. This is due to the fact that factors such as the Outside Setback and the K-Factor

become useless as the apex of the bend moves to infinity. Attempting

to calculate the allowance for a hem like this will just lead to

frustration. Instead a rule of thumb of 43% material thickness is used

when calculating the allowance. For example if our material is .0598”

and we want to achieve a 1/2” hem we will take 43% of .0598, .0257 and

add that to the 1/2” giving us 0.5257”. Thus we must leave 0.5257” on

the end of the flat pattern to achieve a 1/2” hem. It should be noted

that this rule of thumb is not 100% accurate. If you are interested in

creating a high accuracy hem you should always bend a sample piece,

measure and adjust your layouts. It’s wise to do this for your

commonly hemmed materials and create a chart for future reference. The

minimum size or length of a hem is going to b determined by your v

opening of your die. It is going to be wise to check your hem length

after bending because the final step of flattening the metal can be a

bit un-predictable in terms of how it stretches and flattens. Using a

standard minimum flange length should get you close enough for most

applications. Remembering the Air Bend Force Chart the minimum flange length for an acute tool is:

No comments:

Post a Comment